| Availability: | |

|---|---|

| Quantity: | |

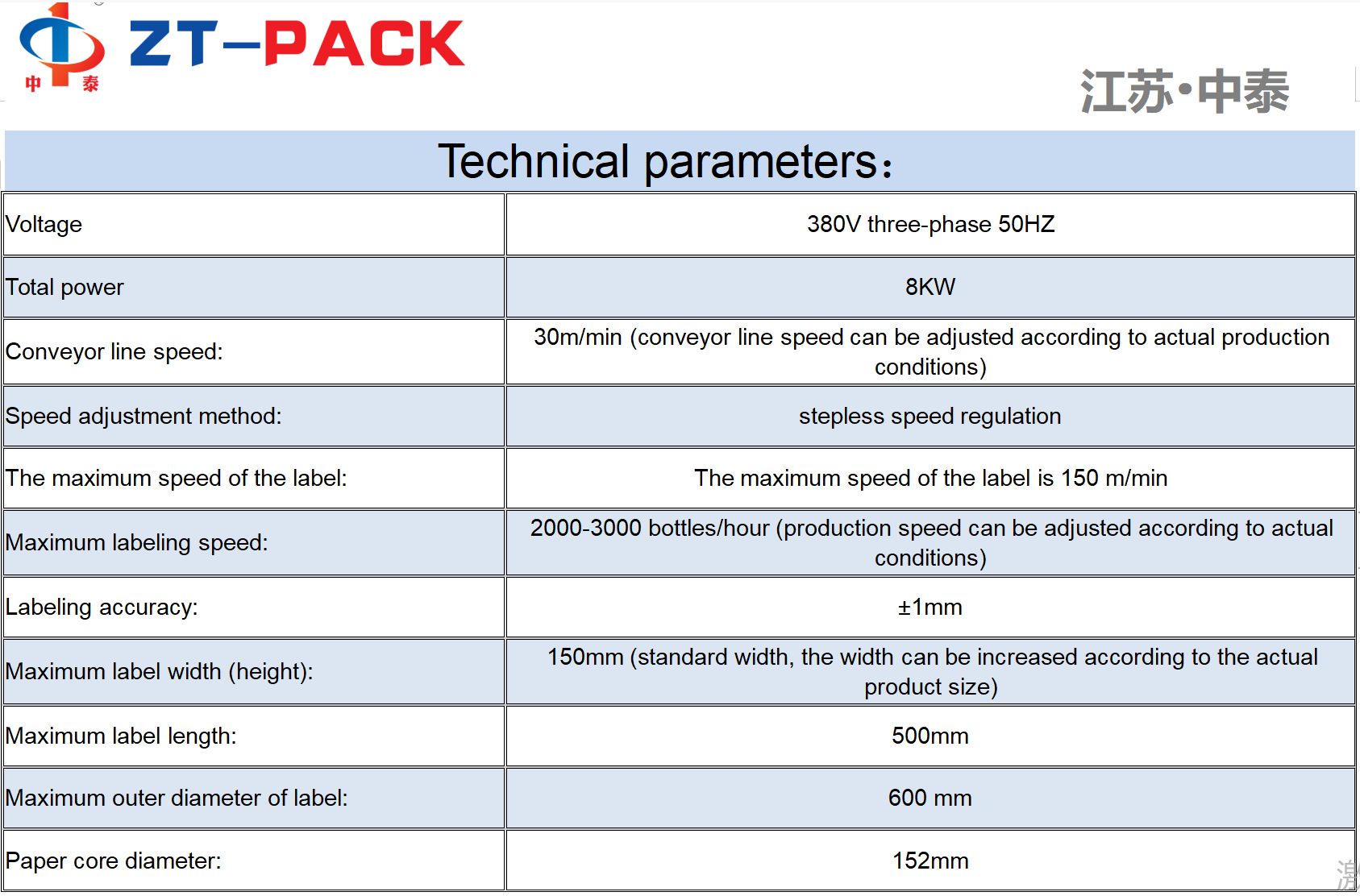

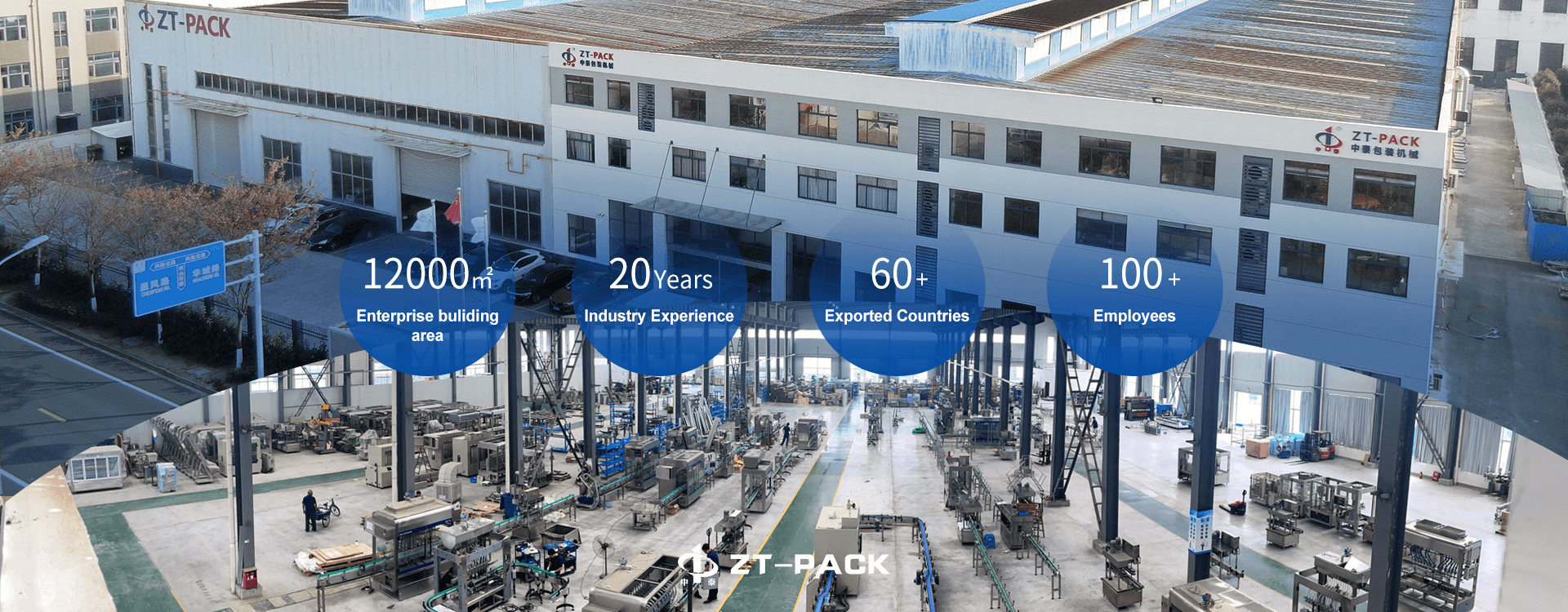

ZT-PACK

Machine Name : Full Automatic Rotary High Speed Labeling Machine

1. This machine automates the labeling process for various types of bottles, making it suitable for different container and label materials. It caters to users with diverse container needs and is cost-effective for mass production and integrated operations.

2. The equipment's advanced design allows for easy bottle replacement, star wheel and guide plate replacement, and manual-to-automatic speed control.

3. The plate of up pressure and down holding accurately positions the container in different locations.

4. Quickly and simply change the configuration components for different containers and labels.

5. The label station is designed for one-time usage and storage.

6. The equipment's operation panel features an LCD touch screen for easy man-machine conversation. The operator can access all operation parameters, including speed, production capacity, and glue water temperature.

7. This device uses an automatic helicoid conveying system for bottles, providing a spacious operation area. The container can be adjusted for multiple gestures at once with a simple brush plate adjustment device.

8. The machinery's lubrication components are made simpler and more reliable with a centralized lubrication system, ensuring a longer machine life. Maintenance is also made easy and convenient.

9. The host has been designed with a rear-mounted cam to replace the bottle-type, and a pneumatic nose tight card for added convenience.

10. The design includes complete overload protection and multi-point fault protection devices to ensure the safety of the operator with alarm sounds and lights.

11. The biaxial screw propeller system ensures a stable and smooth high-speed bottle filling process.

12. A specialized membrane material constant tension detection and feedback control system guarantees high-quality labeling for general membrane materials.

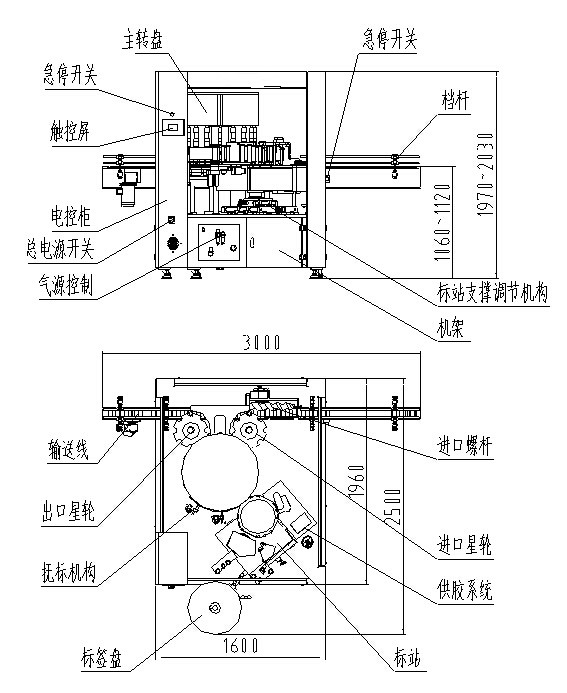

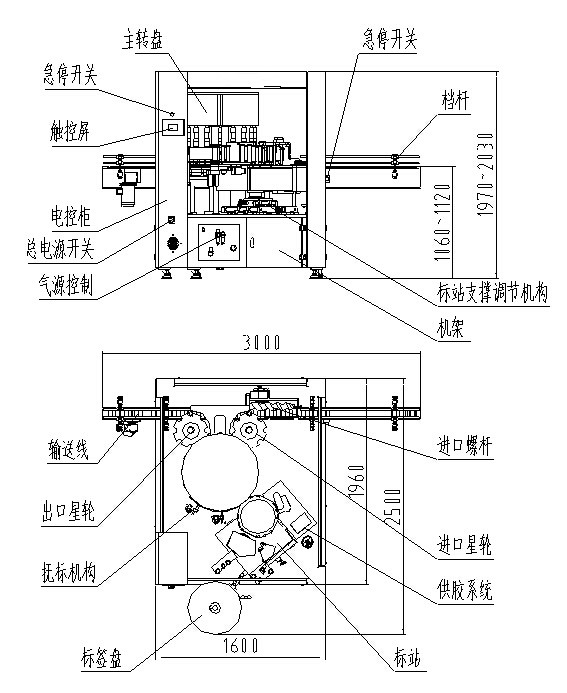

Layout drawing :

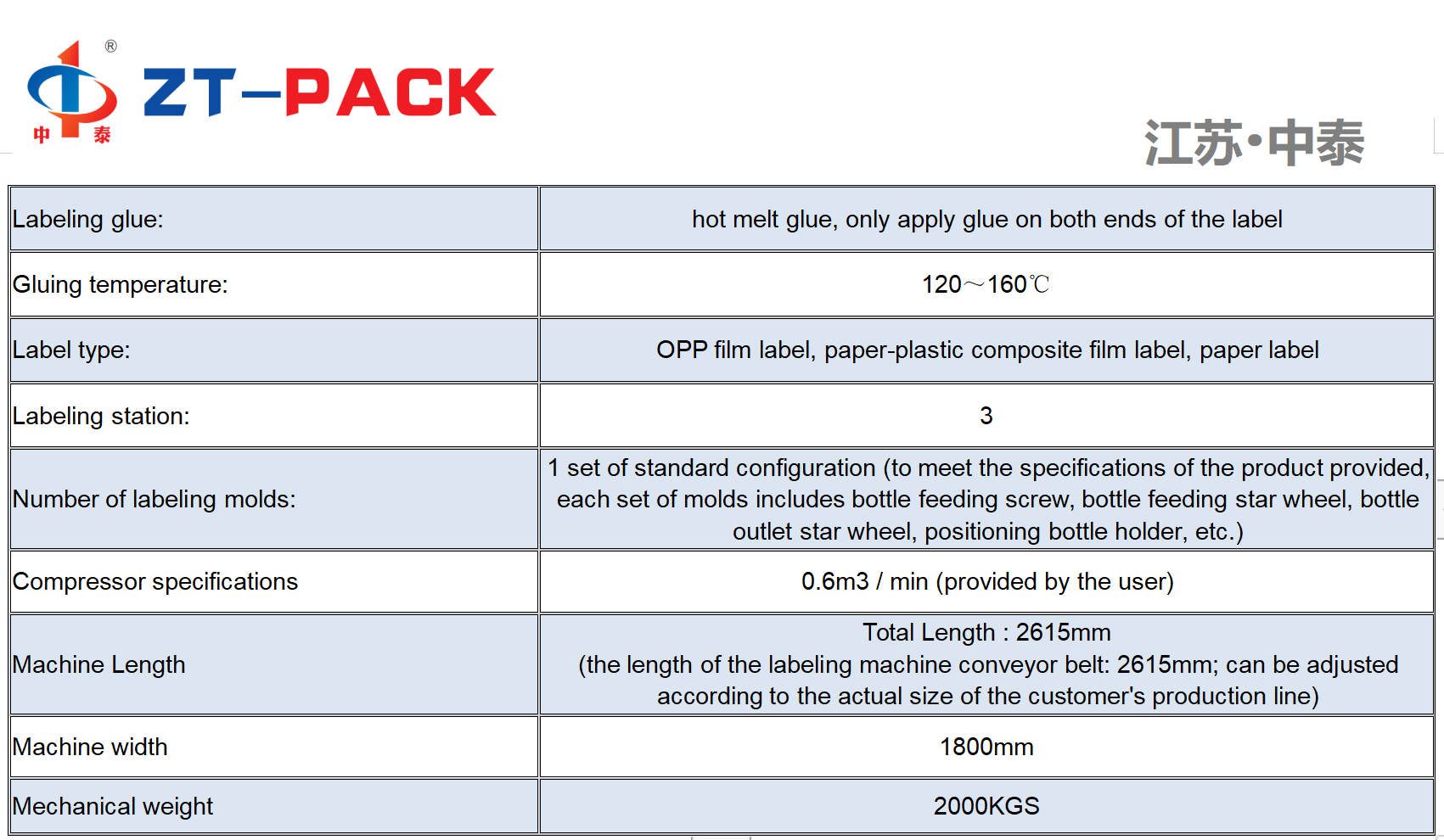

Machine Name : Full Automatic Rotary High Speed Labeling Machine

1. This machine automates the labeling process for various types of bottles, making it suitable for different container and label materials. It caters to users with diverse container needs and is cost-effective for mass production and integrated operations.

2. The equipment's advanced design allows for easy bottle replacement, star wheel and guide plate replacement, and manual-to-automatic speed control.

3. The plate of up pressure and down holding accurately positions the container in different locations.

4. Quickly and simply change the configuration components for different containers and labels.

5. The label station is designed for one-time usage and storage.

6. The equipment's operation panel features an LCD touch screen for easy man-machine conversation. The operator can access all operation parameters, including speed, production capacity, and glue water temperature.

7. This device uses an automatic helicoid conveying system for bottles, providing a spacious operation area. The container can be adjusted for multiple gestures at once with a simple brush plate adjustment device.

8. The machinery's lubrication components are made simpler and more reliable with a centralized lubrication system, ensuring a longer machine life. Maintenance is also made easy and convenient.

9. The host has been designed with a rear-mounted cam to replace the bottle-type, and a pneumatic nose tight card for added convenience.

10. The design includes complete overload protection and multi-point fault protection devices to ensure the safety of the operator with alarm sounds and lights.

11. The biaxial screw propeller system ensures a stable and smooth high-speed bottle filling process.

12. A specialized membrane material constant tension detection and feedback control system guarantees high-quality labeling for general membrane materials.

Layout drawing :

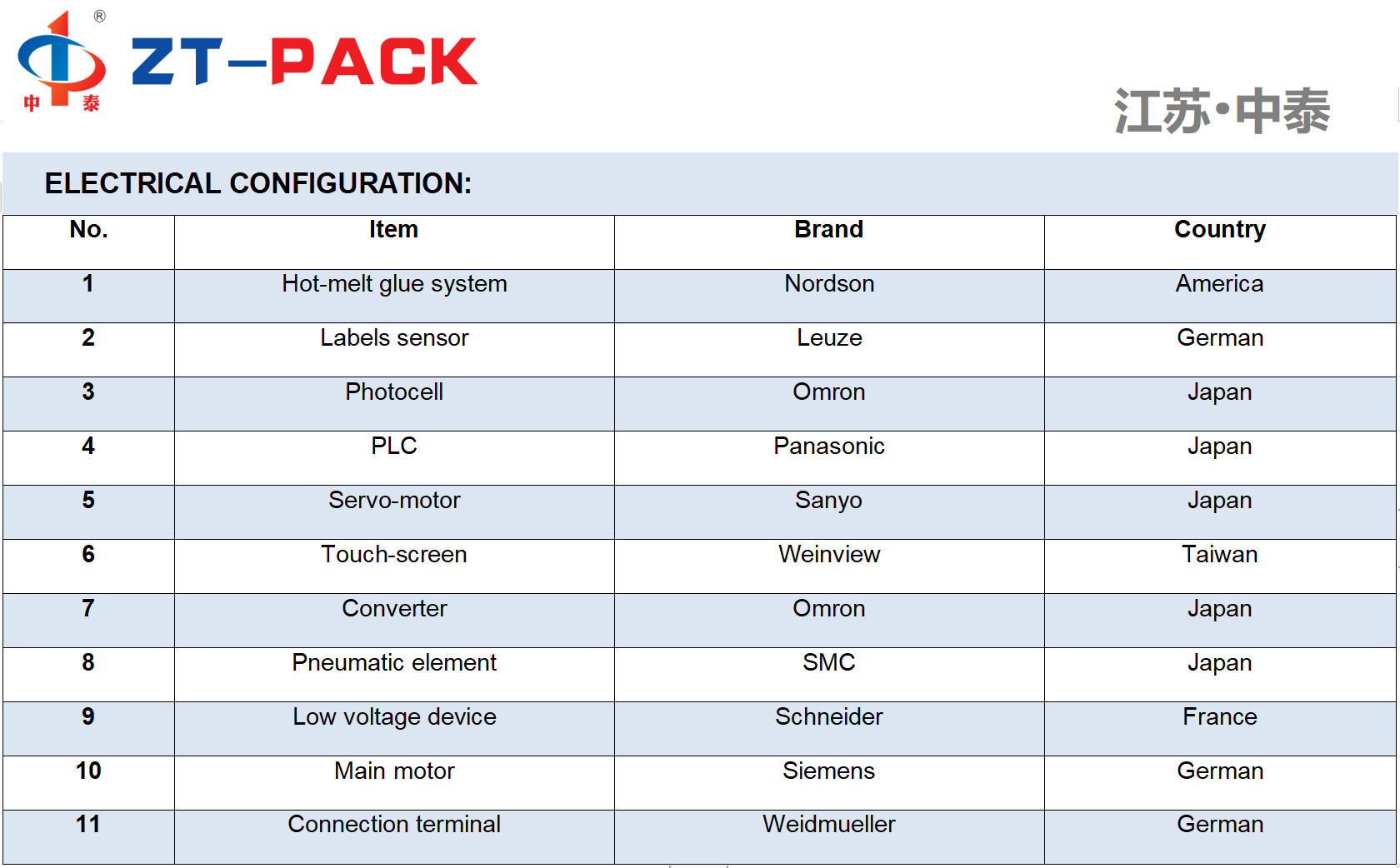

After-Sales Support

With the expansion of the global market, ZT-PACK will, relying on six domestic and overseas service centers, provide technical support and after-sales services to customers all over the world to protect the development of customers’ business.

Packaging things

When the machine is shipped, it is packed in a wooden box, which is strong and not easy to break. Professional forklift workers are responsible for loading the trucks to ensure that the machines will not be damaged during loading.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com